| |

Quick And Direct Information |

|

|

| |

|

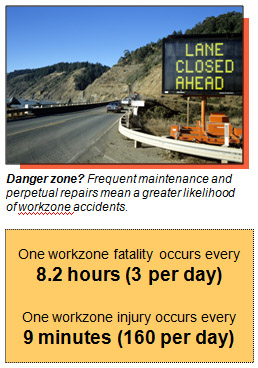

Workzone accidents and incidents occur at an alarming rate. Few would argue that even a single death or injury is too many, so what can be done to address this problem?

Workzone accidents and incidents occur at an alarming rate. Few would argue that even a single death or injury is too many, so what can be done to address this problem?

How bad is the problem? Consider these grim statistics:

- 50% – increase in work zone fatalities

from 1997 to 2004.

- 115,000 – number of work zone crashes annually.

- 1,068 – number of work zone fatalities.

- 49,620 – number of people injured in work zone crashes.

-

Over 90% – work zone fatalities involving motorists, not construction workers.

Perpetual repairs and frequent maintenance means a greater likelihood of accidents. The solution…? Concrete pavements.

Concrete pavements require the least amount of maintenance or repair compared to all other types of pavements. Current design methods and construction techniques mean that concrete pavements will require relatively low maintenance for the life of the pavement (avg. 30-40 years).

Lower-quality pavements, require perpetual maintenance to fill potholes/repair cracking and resurfacing about every 8-14 years. The resulting lane closures and extended work zones greatly increase the likelihood of work zone accidents, as well as traffic congestion.

Between 1982 and 2002, there was a 79% increase in vehicle miles traveled in the United States. In stark contrast, the number of highway lane miles increased only 3 percent. ��

With lane capacity trailing so dramatically, the result is more congestion and more rapid deterioration of the roadways. Further complicating things, some agencies—in search of low-cost alternatives—turned to short-term paving solutions. It may seem like there’s no way out of the repair and resurface cycle.

All pavements eventually need repair or replacement, but what sense does it make to use materials that wear out prematurely or need constant maintenance?

All pavements eventually need repair or replacement, but what sense does it make to use materials that wear out prematurely or need constant maintenance?

��Now, more than ever, it makes sense to use concrete. Consider that pavement preservation accounts for 31.5% of the National Highway System’s capital expenditures (Table 1). This expenditure is directly proportional to the number of work zones. But the dollars and the number of work zones can be reduced by using concrete pavement.

To reduce traffic congestion, we need more capacity, and to get more capacity we have to start investing in quality pavements that have a long life and do not require such a large allocation of highway dollars to preserve the existing system.

If the present trend continues—there will be little money left for much of anything except constantly maintaining, repairing, and replacing existing pavements. If you’re outraged about workzone fatalities and injuries, or simply fed up with frequent road repairs or the number of work zones, let your public officials know about it.

Printer-Friendly Information: |

|

- “Seventh Annual National Work Zone Awareness Week - Work Zone Safety Fact Sheet”, Federal Highway Administration, http://safety.fhwa.dot.gov/wz/nwzaw_events/factsheet06.htm, April 20, 2006.

- “Status of the Nation's Highways, Bridges, and Transit: 2004 Conditions and Performance”, Federal Highway Administration, http://www.fhwa.dot.gov/policy/2004cpr/, July 5, 2006.